Modular Rooflight for DfE framework

It has been recognised that a number of schools are failing to deliver…

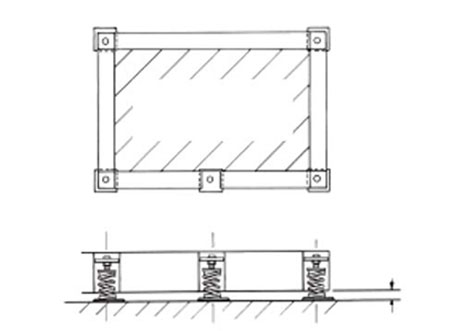

Type TIB

An inertia base is normally required when vibrating plant is required to be isolated with high deflection mounts, typically above 10mm deflection. If plant, such as a pump, is placed on springs without a frame base, it will be unstable.

An inertia base is a frame base into which concrete is poured, which increases the mass of the base, consequently damping down the inertial forces of the plant. The increased mass of the concrete in the base also lowers the centre of gravity of the combined structure, decreasing the base dimensions required to achieve stability. The height of the frame of the base must be at least of the longest dimension between supporting mounts.

Type TIB Inertia bases comprise a frame section manufactured from folded steel sheet typically mm thick. Mounting plates are manufactured from 10mm thick plate. Reinforcing bars are fitted into the bases. The base would normally be finished with grey or red primer ‐ other finishes can be applied as required. Concrete would be supplied and poured into the bases by others.

The base should be placed on a fixed former prior to pouring. Following curing of the concrete, the base should be lifted and the mounts fitted. Height adjustment and levelling of the base can be achieved by adjusting the fixed nut on the mounts, maintaining a minimum dimension of 25mm between the bottom of the base and the supporting structure. We would recommend that the base is temporarily fixed solid by chocks between the bottom of the base and the supporting structure prior to installation of equipment on the base. Following fitting of the supported equipment the chocks should be removed and the base levelled. The bases may be fitted with open springs, restrained springs or neoprene mounts.

Slide table to view more

Dimension & Weight Table

[table id=54 /]

It has been recognised that a number of schools are failing to deliver…

Who are Constructionline? Constructionline have been supporting thousands of construction businesses for over…

New Approved Document O In December 2021, the government announced changes to the…

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |