Modular Rooflight for DfE framework

It has been recognised that a number of schools are failing to deliver…

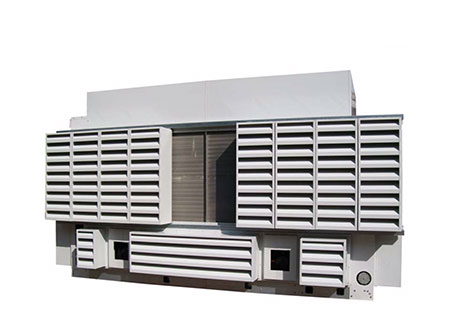

Type AE

We produce high quality acoustic enclosures tailormade for each application. We do not have any standard sizes for the width, height or length of the enclosure.

The panel design is determined by the acoustic and aesthetic requirements of the clients and may be interlocking or mounted within a framework.

Slide table to view more

[table id=43 /]

As tested by Sound Research Laboratories Ltd in accordance with BS ENO 140‐3:1995

The enclosures may be paint finished. Our standard finish is epoxy polyester powder coat with a appropriate primer of alochrome or etch primer. All colours can be provided with delivery subject to availability. Other finishes are available on request.

Standard door furniture is ʻKasonʼ or similar, but we can accommodate any fitments currently available. Handles may be provided to accommodate suitable lock barrels.

Double‐glazed windows can be fitted where required and are available with safety, laminated or wired glass as necessary.

Acoustic seals are fitted between all panels and doors, and frames are normally manufactured from neoprene.

We can also offer a panelling system for acoustic enclosures. The panels are self‐supporting and incorporate a jointing system. The panels can be supplied with a solid or perforated face.

The panels would be finished in powder paint or plastic coat to a standard Dobel colour.

The system can include single‐ or double‐glazed windows and single or double doors either solid or glazed. The system can also be used for noise barriers and screening, cleanrooms and factory work refuges.

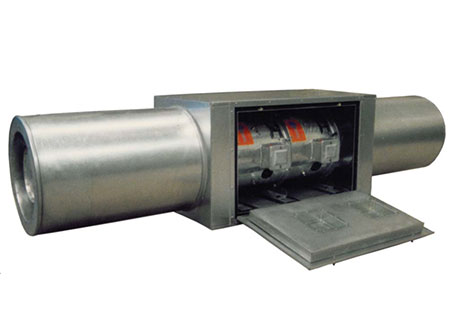

The enclosures normally consist of acoustic panels comprising an outer layer of galvanised steel or aluminium sheet with an acoustic infill retained behind perforated or expanded galvanised steel or aluminium sheets.

The infill would be inorganic mineral wool semi‐rigid slabs with a glass fibre tissue face.

The fibre would be inert, vermin‐, rot‐ and moisture‐ proof, non‐combustible, not support bacterial growth and packed to a density of not less than 45kg/m3.

The infill has been tested for fire and has a Class 1 spread of flame as measured to BS476: Part 7: 1971.

If required, the inner lining of the panels may be manufactured from a solid material instead of the standard perforated or expanded sheet.

The enclosure may be supplied complete with intake and exhaust attenuators and/or cowls and louvres.

They may be self‐ supporting or built into an adjacent structure.

We can provide an acoustic enclosure complete with plant supplied by our client fitted into the enclosure.

The enclosures can be manufactured from a variety of materials such as stainless steel, galvanised steel, aluminium and polyvinyl chloride (PVC) or plastic‐ coated steel.

We can totally enclose fans and air handling equipment supplied to us by others to limit the amount of noise breakout to the areas surrounding the fans.

The enclosures would normally incorporate flexible connections and anti‐vibration mounts with hinged or removable access panels for maintenance.

We would install a junction box external to the unit.

It has been recognised that a number of schools are failing to deliver…

Who are Constructionline? Constructionline have been supporting thousands of construction businesses for over…

New Approved Document O In December 2021, the government announced changes to the…

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |